BLDC stands for Brushless Direct Current. BLDC technology, in general, has been in the market for a couple of decades and it is widely implemented in industries needing high torque motors. What was missing so long is its application in the ceiling fans.

A motor is essentially made up of two parts: A rotor and a stator. Rotor is the moving part (inside) of a motor while stator is a stationary (outer) part. The two parts use magnetic/electromagnetic energy to create movement/rotation just like how two magnets interact to create rotational motion (as shown in the gif below). And this is how a motor works. Winding copper/aluminium wire around a steel/iron metallic piece typically creates the electromagnets for stator. The magnet for the rotor can be permanent magnet or electromagnet depending on the type of motor.

When it comes to saving energy, most of us generally overlook ceiling fans. We see big appliances like air conditioners or heaters with suspicion for surreptitiously piling up the electricity bill. What we fail to understand though is that the ceiling fans are all-weather appliance—which keeps running all through the day (and even night)—thus cumulatively consume more electricity than we assume it to be.

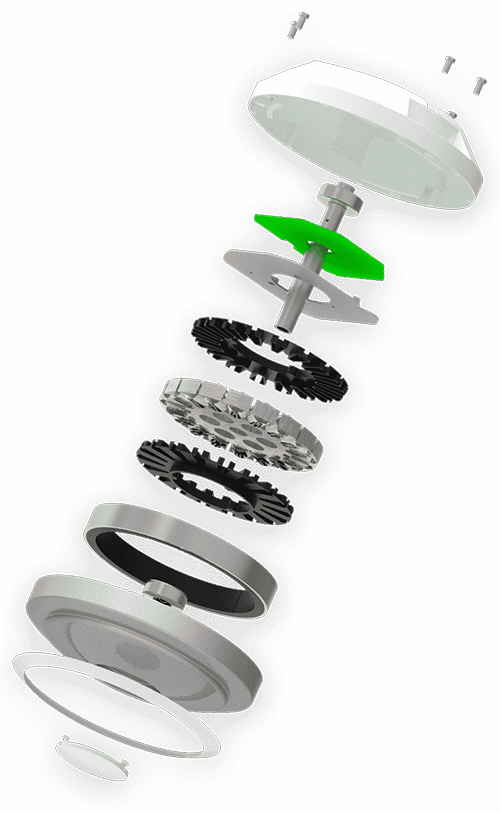

For years, ceiling fans used to come with the same hardware of induction motor which typically consumed 70-80 watts for a standard ceiling fan. But in the last few years, a new technology called BLDC is being used to make fans consume a lesser amount of energy, without compromising much on the air delivery. BLDC stands for brush-less direct-current motor, a special type of motor which has permanent magnet instead of electromagnets found in a conventional induction motor. BLDC motor has important advantages over induction motor like low electricity consumption, lesser noise generation and better lifespan.

Bureau of Energy Efficiency (BEE) is the government agency that promotes, develops and monitors various programs for improving energy efficiency. They are the ones who give energy star ratings which you typically see on electronic appliances like ACs, refrigerators, washing machines etc. BEE has started a program called Super-Efficient Equipment Program (SEEP) in February 2012 with the intent to rate appliance on its energy consumption parameter and promote energy-efficient consumer appliances. Ceiling fans were the first target of this program. Since the launch of this program, many startups have come with the idea of ‘BLDC fans’ which are usually 5-star rated and thus are highly energy efficie.

Efficiency is all about achieving the same results while using lesser electricity. Typical ceiling fans made with the conventional design are made of single-phase induction electric motor. Most of the prevailing fan manufacturers used aluminium than copper in the fan, as it is cheaper. But aluminium is less energy efficient. The end result is that most of the traditional technology fans consumed about 70-80 watts of electricity. The air delivery of these fan ranges between 210 to 250 m3/min. After the BEE launched the SEEP program, these manufacturers had to increase copper content and also improved blade designs in a bid to enhance energy efficiency. The result was BEE 5 star rated fans that would consume about 25-40 watts of electricity which were also called super-efficient fans.

The super-efficient 5-star rated BLDC fans that are available in the market generally use a different type of motor (BLDC motor) which further facilitates efficient blade designs, making ceiling fans far more efficient. Most of the BLDC ceiling fans are 5-star rated consuming 25-40 watts of energy, which is about 40-70% less than the regular old fans. Also, BLDC fans do not require installation of an additional regulator which saves 200-500 rupees upfront. Instead, they are controlled wirelessly with the help of remote just like air conditioners.

When BLDC fans were newly launched the air delivery used to be 210-230 m3/min but with the advancement in the technology, manufacturers have able to amp up the air delivery and you can now find BLDC model air delivery between 230-270 m3/min from reputed brands like Atomberg and Versa Drives.

We are the business of revolutionizing India’s home appliances, by solving one problem at a time. Our secret weapon? Asking the right questions. Pointed questions about how we can make our customers’ daily lives easier. Questions that require granular answers and thoughtful product design.

Airey Fans © 2023. All Rights Reserved.